Link-Pipe

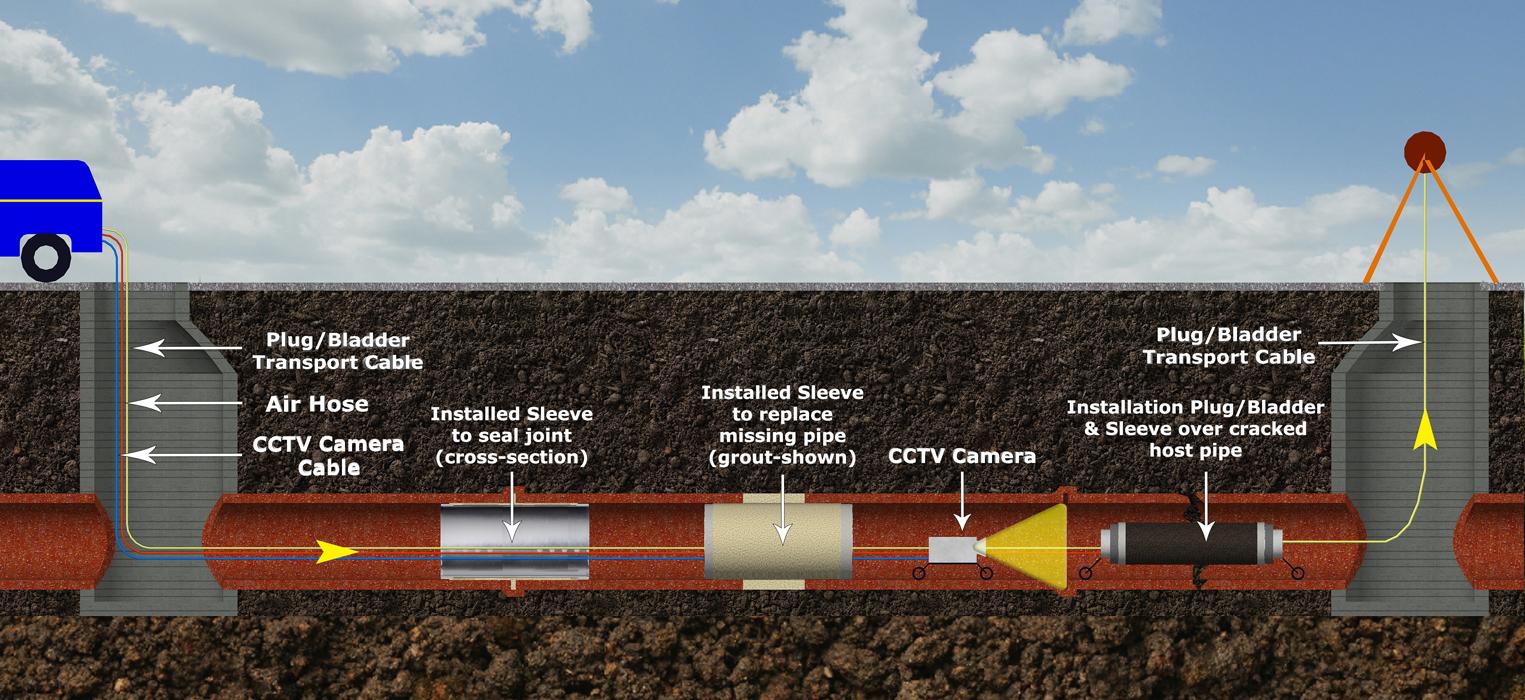

Link-Pipe Incorporated (LPI) specializes in designing and manufacturing no dig trenchless pipe repair products.

Direct Links

Experienced

At Link-Pipe, we have accumulated over 34 years of skilled background and experience in commercial and municipal sewer repair. We have been part of successful trenchless sewer repair projects all across North America. These projects have varied in scale, meaning that we are able to provide our services to a range of project types, and to cater to your specific needs.

Patented Technologies

Our patented technologies, as well as our demonstrated dedication to high quality results and customer service, keep us at the top of the industry. This is why we have managed to maintain a consistent track record of satisfied customers who continue to bring us new projects. It is also why we are the best local option for trenchless sewer repair. We are overzealous about customer satisfaction, and it shows clearly through the manner in which we conduct our business. We guarantee that our services will leave you fully satisfied!